SHEAROGRAPHY LASER TESTING

Laser NDT Solutions for Advanced

Materials and Processes

NDT PRODUCTS

SHEAROGRAPHY & HOLOGRAPHY

LTI offers a full range of standard and custom solutions for your nondestructive testing requirements.

From small portable instruments to massive robotic and gantry scanning systems LTI has the products, software and fabrication expertise as well as the experience to deliver state of the art NDT technology to meet your needs.

SERVICES

EVALUATION STUDIES, NDT ENGINEERING AND NDT SERVICES

TECHNOLOGY

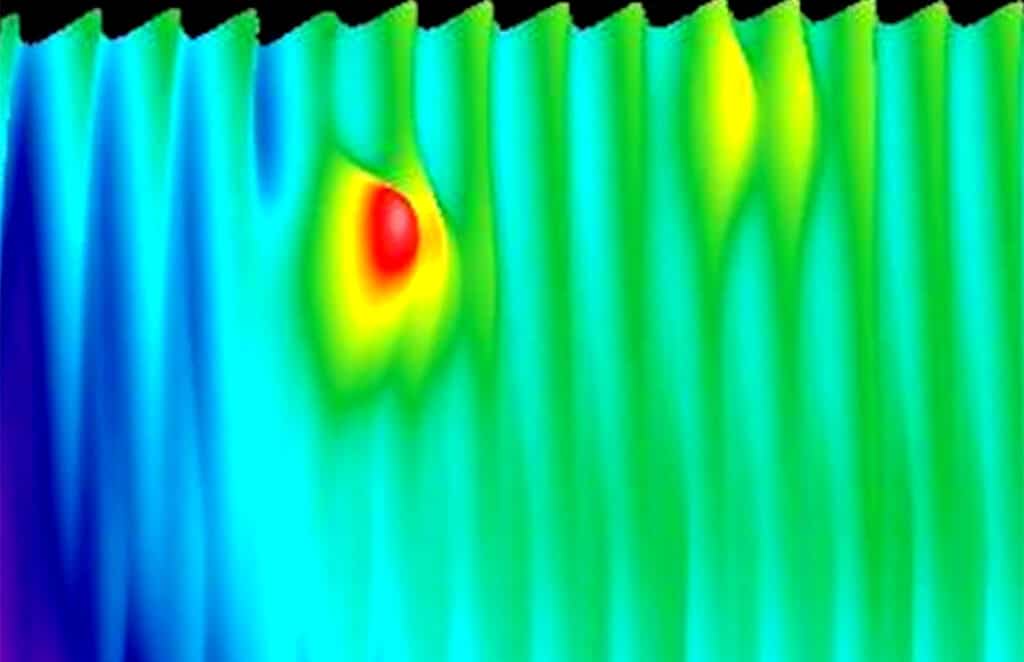

HOW SHEAROGRAPHY WORKS

A Shearography camera images how a test object surface changes shape when a small change in stress is applied. Sensitive to 1nm or 1 billionth of an inch, both surface and sub-surface anomalies are revealed with the right stress change. Shearography NDT is a powerful NDT tool proven in hundreds of applications and major programs transportation, defense and power industries since 1987.

ABOUT LTI

SHEAROGRAPHY APPLICATIONS

When it’s mission critical, we’re there. Our technology keeps equipment and people safe in a multitude of applications

Spacecraft & Launch Vehicles

Spacecraft & Satelite

Aerospace & Defense

Medical Devices

Wind Turbines